by Bob Kozak* (Atlantic Biomass, LLC) In Part 1 of this 3-part series we discussed how “Goldilocks Oil Pricing” is causing major problems for the US fuel ethanol industry. In this Part 2 we’ll discuss why US R&D hasn’t been able to produce good solutions and offer some ideas for a way forward.

The technical solution is very simple to describe.

Raise NET Income for farmers and producers by reducing Feedstock and Production Costs.

But, why haven’t we reached this goal?

If we were doing R&D correctly, we’d have already produced the solutions.

Where have we gone wrong?

Simply put, the US R&D system, both governmental and private, limits imagination and research by limiting most funding to programs within preselected pathways. These pathways are mostly selected by members of Congress, the Executive Branch, and business executives within the Silicon Valley environment for reasons having little to do with advances in experimental science. Instead, maintaining stock performance and campaign contributions, keys to maintaining high end jobs, seems to have more to do with what technologies are preselected.

Here are three examples of how this preselected, non-scientific approach has seriously harmed the nation's competitive science and technology advantage.

Example #1: From Performance Standards to Preselected Technologies: When the Obama Administration took office and moved to revise fuel economy standards, they threw out the technology neutral performance goal approach established by the Clean Air Acts of 1970, 1977, and 1990. Under the Clean Air Act, vehicle manufacturers were not told how to meet air quality standards. Instead, they were given performance goals, for example, to reduce 90% of current emissions with whatever science and technology they could invent or utilize. Catalytic converters, unleaded fuel, and computer controls which successfully worked together to help all metropolitan areas except Los Angeles and Houston meet ozone reduction goals, were not stipulated anywhere in Clean Air Act legislation or regulations.

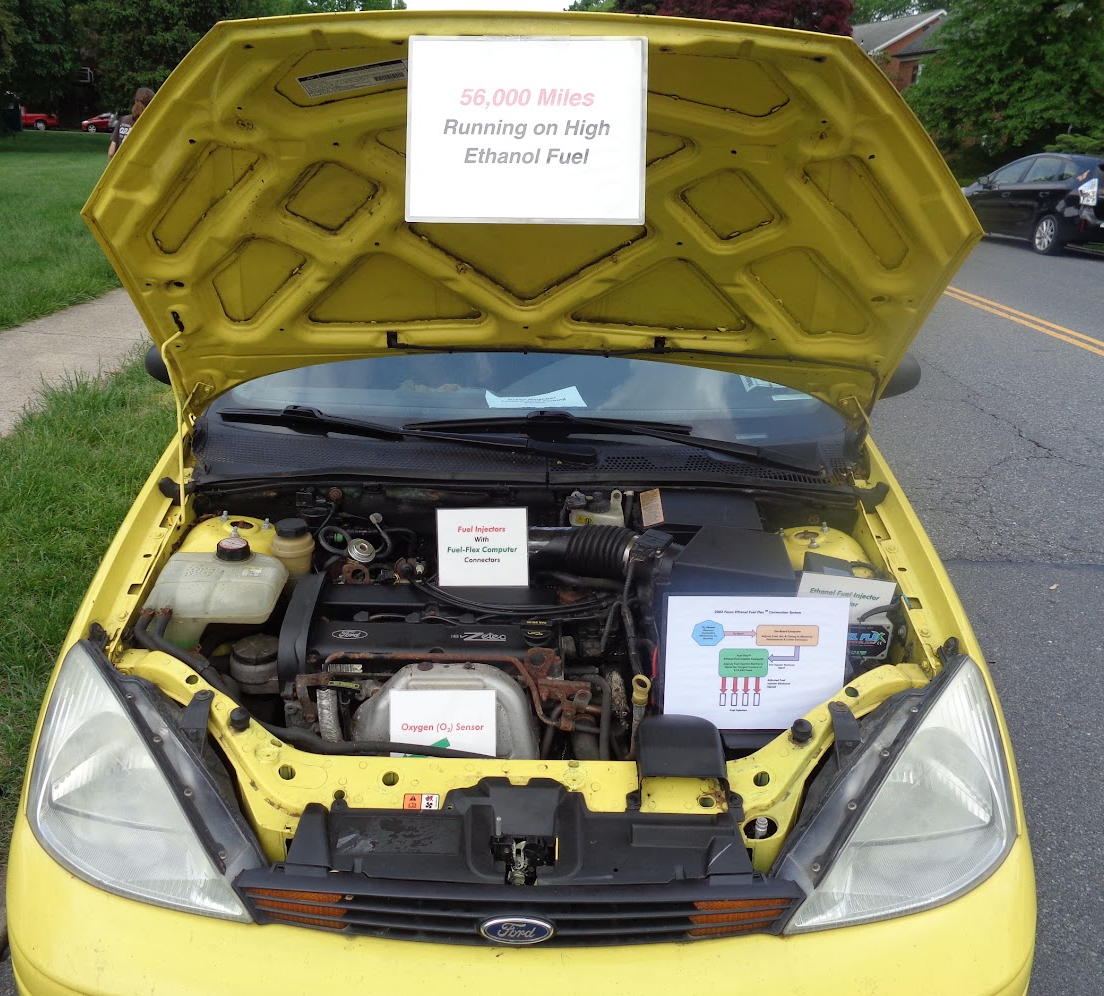

use E85 without changing

installed Clean Air Act components

Photo: JIvancic

Under the Obama Administration, the fuel economy standards were rewritten to favor only one preferred technology, electric vehicles, before any consideration whether other technologies, such as non-food biofuels could produce sizeable CO2 reductions faster.

In addition, Obama officials assumed the needed electricity could be provided at near carbon neutral levels. Finally, no analyses (polls, focus groups, etc.) were performed to see if the US vehicle buying population would accept having their purchase options restricted. As we’re now seeing, a significant majority of the US population doesn’t want to purchase electric vehicles. And, those vehicles purchased have had a minor effect on CO2 reduction because of their “non-green” electrical sources. However, their much lower than expected sales are probably good for the electric production industry. The growth of AI and crypto driven data centers has created a US electrical production shortage that is only being alleviated by substantial Canadian imports.

Example #2: Starving Basic Science for Commercial Loan Guarantees: The US government through agencies such as the National Science Foundation (NSF), National Institutes of Health (NIH), Department of Agriculture (USDA), Department of Energy (DOE), National Oceanic and Atmospheric Administration (NOAA), National Aeronautics and Space Administration (NASA), and the Environmental Protection Agency (EPA) have long been the primary supporters of Basic Science R&D in the United States. Basic Science under Administrations such as Roosevelt or Eisenhower did not have to meet business goals such as Return on Investment (ROI). Instead Basic Science was seen as the necessary base from which all new applied sciences and technologies would grow. Academic and business researchers would read the latest articles and have Eureka moments when they saw something that would improve what they were working on.

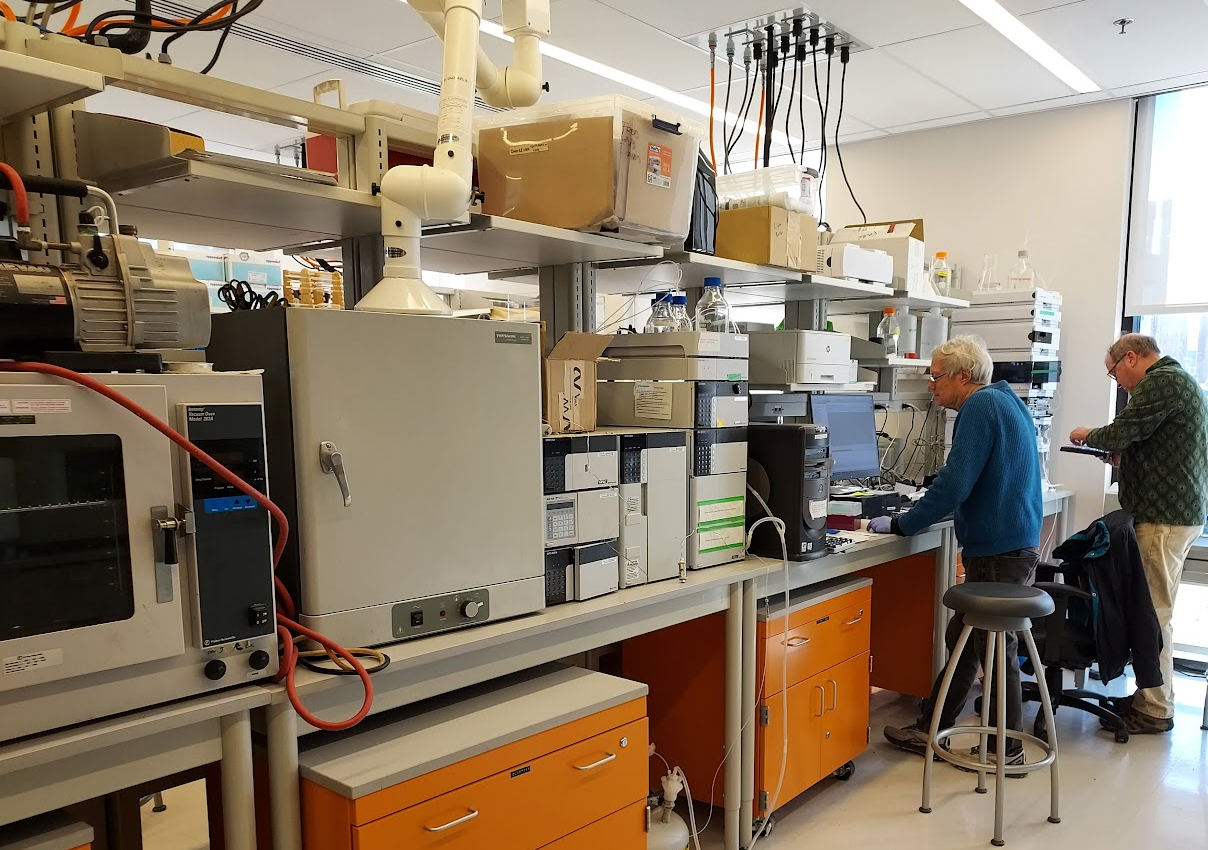

research at Hood College

Frederick, MD photo: JIvancic

Then, sometime after the Carter Administration, which had increased government funding of academic and business science to the highest levels (as percentage of GDP) ever, Silicon Valley venture capital ideas started to invade US government R&D policy and funding operations. Instead of basic science being seen as intrinsically necessary for the future wealth and well being of the country, it came to be seen as a high-risk/low gain endeavor. Slowly at first and then more rapidly, Federal science funding programs had to respond to ROI goals to retain Administrative approval and Congressional funding.

The result? I think you can predict it.

To keep their programs funded, government officials moved away from “high-risk” basic research to “lower risk” applied down stream business R&D. Out went basic research in topics such as enzyme or drug development and in came loan guarantees for electric battery or drug production plants.

According to the latest Organization for Economic Co-Operation and Development (OCED) numbers reported by the National Science Foundation in 2024 (The State of U.S. Science and Engineering 2024), the US spent only 15% ($119 billion) of its total R&D 2021 (latest year available) budget on basic research. In contrast, private business applied R&D reached about $600 billion.

Example #3: Effects on the Biofuel Industry: Biofuels were favored by the George W. Bush Administration (2001-2009). Highlights included: 10% ethanol replacing the long-life carcinogen MTBE (methyl tertiary-butyl ether in gasoline); President Bush speaking highly of switchgrass as a feedstock in his 2005 State of the Union Address; and a cellulase enzyme improvement program sponsored by the Department of Energy. However, because none of these programs had solid legislative backing, no R&D infrastructure was established for the scientific improvement of biofuels. (Contrary to general opinion the 2005 Renewable Fuels Standards act did not establish biofuel use standards or a research and development infrastructure. All it did was to create a tax credit program based on a small number of production pathways.)

So, after President Bush finished his maximum of two terms, rather than establishing long term undergraduate and graduate programs at American land-grant and engineering schools to improve biomass crops, hydrolysis enzymes, fermentation organisms, or biomass conversion hardware, each succeeding Administration provided minimum funding for “of the moment” bioproduct ideas that look good surrounded by words like disruptive in media releases.

Often, the research areas were extremely limited to preselected technologies or processes such as pretreatment and did not offer room for system-wide innovation. At the same time government funding for electric battery plants loan guarantees, nuclear power demonstration projects, and fracking technology improvements completely dwarfed renewable biomass fuel development. And this was while each Administration proclaimed that their energy policies were/are “all of the above” or words to that effect.

Mount Vernon photo: JIvancic

This has been going on since 2009, fifteen years ago. As anyone who visits this website knows, there has been pitifully little change in the commercial production of renewable biomass based fuels since then.

We’re still using centuries old processes and tools to process corn kernels or sugar cane to extract starch or sucrose that is fermented to ethanol using yeast much as homo sapiens (and Neanderthals?) have been doing for thousands of years.

The ethanol is distilled to very high purity (Remember bootleggers? Just bigger stills.) and added to petroleum refined hydrocarbons in quantities largely between 10% and 15% (yes, like a wine) to improve combustion through oxygenation and octane enhancement. Oh, and yes, CO2 emissions are reduced compared to 100% petroleum based gasoline.

So where are the fuels based on non-food perennial crops? Where are the integrated biomass and CO2 biorefineries? Where are the profits?

Biomass to Biofuel Research is Hard

Simply put, we’ve stagnated. Why? As someone who has been tenaciously working on this for most of the century, I can say it’s much harder than we thought. Remember, evolution has had millions of years to develop biomass that is sturdy and not that susceptible to bacteria. Ever look at a cutting chain after it brought down a hardwood tree? Ever try to chop even an innocent looking grass like Miscanthus?

experimentation

photo: JIvancic

Unfortunately, overcoming these well crafted evolutionary derived barriers within a venture capitalist’s timeframe, budget, and ROI expectations is not possible. This is not something that AI and some coding can accomplish. This can only be done by acquiring data through empirical experimentation.

To succeed, the following goals have to be a key part of Government and private sector R&D Leadership.

- Maintain a perseverance to keep going despite major setbacks,

- Create and maintain a solid and ever expanding basic science understanding that will lead to straightforward solutions,

- Instill an inventive mindset willing to consider alternatives to preconceived ideas,

- Keep driving for a system-based simplicity,

- Instill a desire to work together with everyone,

- Do not use ROI goals for basic research, and

- Maintain solid and consistent funding,

Lessons of the Manhattan Project

Or, if you will, follow how the Manhattan project was conducted in the 1940s. In about five years the discoveries of Rutherford, Curie, Lawrence, Fermi, Szilard and others, which had taken over forty years of unrelenting thinking and experimenting, were transformed into weapons of unbelievable power that were produced in the thousands. The project also created and maintained great schools of physics, chemistry, and engineering in the United States.

How did this happen? Besides the consistent and more than adequate funding, all the objectives listed above guided their work. Here’s a key example of how that made the project a success.

Achieving the high concentrations of uranium and plutonium necessary for powerful explosions were probably the greatest roadblocks that greeted the project at its inception. (Chain reactions had already been demonstrated.) Mined uranium deposits are generally in the range of .02% - .1% of the rocks they are in. Highly enriched “weapons-grade” uranium is up to 90%, or 900 times greater. Quite a concentration challenge awaited them.

Achieving the high concentrations of uranium and plutonium necessary for powerful explosions were probably the greatest roadblocks that greeted the project at its inception. (Chain reactions had already been demonstrated.) Mined uranium deposits are generally in the range of .02% - .1% of the rocks they are in. Highly enriched “weapons-grade” uranium is up to 90%, or 900 times greater. Quite a concentration challenge awaited them.

At the start of the Manhattan Project, the concentration technology that seemed to have the greatest chance of success was electromagnetic separation. It used high electrical demand devices called calutrons. In fact so much electricity was needed that the TVA (Tennessee Valley Authority) hurriedly built a new electrical production dam (Douglas Dam) near the Oak Ridge nuclear R&D center in eastern Tennessee. While this technology had a great pedigree, it had been developed by Nobel winner Ernest Lawrence at the University of California Berkley (sort of the “in-house” favored team at the time), it encountered problems at low-end uranium concentrations.

Seeing this, Robert Oppenheimer (also a researcher at Cal Berkley before the Manhattan Project) and other project leaders quickly gave funding to other approaches. Something called liquid thermal diffusion that was developed by a somewhat outsider competitor, Philip Abelson and the Naval Research Laboratory, showed promise on the lab scale. Quickly built up in parallel with the calutrons it worked well, with low maintenance, at the first stages of concentration. Together, these two systems worked in series to solve the concentration challenge and provide sufficient enriched uranium for over 60 years.

Imagine how World War II might have continued beyond August 1945 if someone in leadership would have denied funding to an alternative approach called liquid thermal diffusion. (The Making of the Atom Bomb, Richard Rhodes, 1987, offers a very good history of the Manhattan Project and the important research on which it was based.)

Working in the Current R&D Environment

With the chances of a return to the heady days of American R&D progress seeming near zero while the current Administration creates havoc at US government research institutions, what can those of us on the cutting edge of biomass to biofuel research do to push forward to a biofuel R&D renaissance?

We have to press the edges of our current research work to produce innovations outside of current inefficient designs.

We at the Atlantic Biomass, LLC led research coalition are attempting to do this by focusing on four of the goals listed above:

- Maintain a perseverance to keep going despite major setbacks,

- Create and maintain a solid and ever expanding basic science understanding that will lead to straightforward solutions,

- Instill an inventive mindset willing to consider alternatives to preconceived ideas, and

- Keep driving for a system-based simplicity,

And what is the commercial focus of our work?

- To produce a cost-effective, simplified integrated process that will allow perennial grasses to be used as feedstocks for SAF production. We are currently testing switchgrass, phragmites, and miscanthus as feedstocks.

Yes, many people would consider this on the edge of what is possible. However, if we or other people do not keep pushing, this result will probably never happen.

We have been fortunate in the past four years to have received crucial, but limited, funding from the Maryland Energy Innovation Institute (MEII) and the DOE STTR Phase I program to investigate this idea. While this funding is directed at improving specific technologies that include; bacterial fermentation, ball milling, and rotary evaporation, the results have led us to look at the overall process from a simplification perspective.

While we cannot present our current results since we have not finished the necessary multiple runs to verify our results and some of the processes involve proprietary R&D, we can share the system perspectives that we have learned. We think they will be important for the future of economical advanced biofuel production.

Atlantic Biomass System Design Goal: Simplify and Reduce Costs

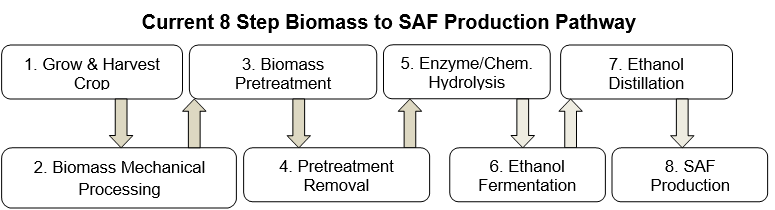

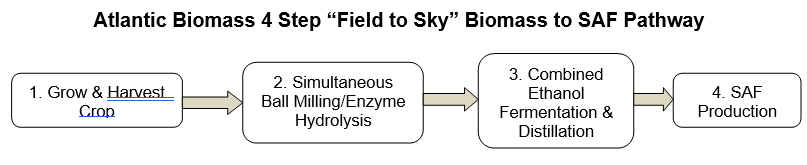

Current biomass to biofuel pathways using field biomass or agricultural residues as feedstocks for SAF or other biofuels/bioproducts via ethanol production generally require eight independent steps. Each one has its own energy use and operational costs. The elimination or consolidation of any of these would offer significant cost savings.

Our work began with a focus on eliminating pretreatment. We think this is important because of the high cost/low benefit ratio of pretreatment.

While most people are familiar with the direct costs of pretreatment, energy and chemical additions, there are also the hidden costs of removing chemicals used in pretreatment. Why, you might ask, must they be removed? Many of them have been shown to be hydrolysis and fermentation inhibitors. So, from a cost standpoint, their contribution to biomass deconstruction is offset by either; a) their reduction in hydrolysis or fermentation efficiency, or b) the cost of removing them prior to hydrolysis.

Photo: JIvancic

Our results, from both batch-fed and continuous steady state runs that combine biomass deconstruction with hydrolysis are promising and we think offer a simplified alternative.

The Atlantic Biomass simplified pathway will have only four steps. As shown below, the pretreatment steps; 2, 3, and 4, are eliminated. In addition step 6, fermentation and step 7, distillation, are combined. This combined process grew out of our addressing some limitations of bacterial fermentation. Besides maintaining optimal fermentation input concentrations it also showed promise in reducing distillation complexity.

Our path forward at the end of our Phase I STTR project is directed at two goals: 1) demonstrate that this system can work in stationary and portable applications, and 2) work with commercial partners to implement it in challenging real-world environments.

All the while we will try our best to:

- Work together, not divide and conquer,

- Keep it simple and get it right,

- Keep testing new improvements and ideas,

- And, most importantly, don’t expect to get rich quick.

We hope that our work and the work of other cutting-edge researchers will be able to fulfill the promise that low nutrient input perennial grasses have offered the biofuel industry. It’s not going to be easy. But, if we keep our eyes on the prize and not get distracted by non-science based preconceptions or venture capital business models, I think we can make it across the finish line.

**Bob Kozak is the founder and President of Atlantic Biomass, LLC, and a co-founder of Advanced Biofuels USA. After working for about 40 years in the transportation, energy, environmental, and government relations industries, he is now focusing on the development of enzyme systems to convert low cost feedstocks into biofuels. He can be reached at atlanticbiomass @ aol.com

Related articles

- Is the “Goldilocks” Cost of Oil Pricing out Corn for Ethanol Production? (Part 1) (Atlantic Biomass)

- Making a Profit on Biofuels at Goldilocks Oil Prices (Part 3) (Atlantic Biomass)

- Pennsylvania research project explores markets for switchgrass (Farm and Dairy)

Nearly 55,000 articles in our online library!

Use the categories and tags listed below to access the nearly 50,000 articles indexed on this website.

Advanced Biofuels USA Policy Statements and Handouts!

- For Kids: Carbon Cycle Puzzle Page

- Why Ethanol? Why E85?

- Just A Minute 3-5 Minute Educational Videos

- 30/30 Online Presentations

- “Disappearing” Carbon Tax for Non-Renewable Fuels

- What’s the Difference between Biodiesel and Renewable (Green) Diesel? 2020 revision

- How to De-Fossilize Your Fleet: Suggestions for Fleet Managers Working on Sustainability Programs

- New Engine Technologies Could Produce Similar Mileage for All Ethanol Fuel Mixtures

- Action Plan for a Sustainable Advanced Biofuel Economy

- The Interaction of the Clean Air Act, California’s CAA Waiver, Corporate Average Fuel Economy Standards, Renewable Fuel Standards and California’s Low Carbon Fuel Standard

- Latest Data on Fuel Mileage and GHG Benefits of E30

- What Can I Do?

Donate

DonateARCHIVES

- February 2026

- January 2026

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- September 2009

- August 2009

- July 2009

- June 2009

- May 2009

- April 2009

- March 2009

- February 2009

- January 2009

- December 2008

- November 2008

- October 2008

- September 2008

- August 2008

- July 2008

- June 2008

- May 2008

- April 2008

- March 2008

- February 2008

- January 2008

- December 2007

- November 2007

- October 2007

- September 2007

- August 2007

- June 2007

- February 2007

- January 2007

- October 2006

- April 2006

- January 2006

- April 2005

- December 2004

- November 2004

- December 1987

CATEGORIES

- About Us

- Advanced Biofuels Call to Action

- Aviation Fuel/Sustainable Aviation Fuel (SAF)

- BioChemicals/Renewable Chemicals

- BioRefineries/Renewable Fuel Production

- Business News/Analysis

- Cooking Fuel

- Education

- 30/30 Online Presentations

- Competitions, Contests

- Earth Day 2021

- Earth Day 2022

- Earth Day 2023

- Earth Day 2024

- Earth Day 2025

- Executive Training

- Featured Study Programs

- Instagram TikTok Short Videos

- Internships

- Just a Minute

- K-12 Activities

- Mechanics training

- Online Courses

- Podcasts

- Scholarships/Fellowships

- Teacher Resources

- Technical Training

- Technician Training

- University/College Programs

- Events

- Coming Events

- Completed Events

- More Coming Events

- Requests for Speakers, Presentations, Posters

- Requests for Speakers, Presentations, Posters Completed

- Webinars/Online

- Webinars/Online Completed; often available on-demand

- Federal Agency/Executive Branch

- Agency for International Development (USAID)

- Agriculture (USDA)

- Commerce Department

- Commodity Futures Trading Commission

- Congressional Budget Office

- Defense (DOD)

- Air Force

- Army

- DARPA (Defense Advance Research Projects Agency)

- Defense Logistics Agency

- Marines

- Navy

- Education Department

- Energy (DOE)

- Environmental Protection Agency

- Federal Energy Regulatory Commission (FERC)

- Federal Reserve System

- Federal Trade Commission

- Food and Drug Administration

- General Services Administration

- Government Accountability Office (GAO)

- Health and Human Services (HHS)

- Homeland Security

- Housing and Urban Development (HUD)

- Interior Department

- International Trade Commission

- Joint Office of Energy and Transportation

- Justice (DOJ)

- Labor Department

- National Academies of Sciences Engineering Medicine

- National Aeronautics and Space Administration

- National Oceanic and Atmospheric Administration

- National Research Council

- National Science Foundation

- National Transportation Safety Board (NTSB)

- Occupational Safety and Health Administration

- Overseas Private Investment Corporation

- Patent and Trademark Office

- Securities and Exchange Commission

- State Department

- Surface Transportation Board

- Transportation (DOT)

- Federal Aviation Administration

- National Highway Traffic Safety Administration (NHTSA)

- Pipeline and Hazardous Materials Safety Admin (PHMSA)

- Treasury Department

- U.S. Trade Representative (USTR)

- White House

- Federal Legislation

- Federal Litigation

- Federal Regulation

- Feedstocks

- Agriculture/Food Processing Residues nonfield crop

- Alcohol/Ethanol/Isobutanol

- Algae/Other Aquatic Organisms/Seaweed

- Atmosphere

- Carbon Dioxide (CO2)

- Field/Orchard/Plantation Crops/Residues

- Forestry/Wood/Residues/Waste

- hydrogen

- Manure

- Methane/Biogas

- methanol/bio-/renewable methanol

- Not Agriculture

- RFNBO (Renewable Fuels of Non-Biological Origin)

- Seawater

- Sugars

- water

- Funding/Financing/Investing

- grants

- Green Jobs

- Green Racing

- Health Concerns/Benefits

- Heating Oil/Fuel

- History of Advanced Biofuels

- Infrastructure

- Aggregation

- Biofuels Engine Design

- Biorefinery/Fuel Production Infrastructure

- Carbon Capture/Storage/Use

- certification

- Deliver Dispense

- Farming/Growing

- Precursors/Biointermediates

- Preprocessing

- Pretreatment

- Terminals Transport Pipelines

- International

- Abu Dhabi

- Afghanistan

- Africa

- Albania

- Algeria

- Angola

- Antarctica

- Arctic

- Argentina

- Armenia

- Aruba

- Asia

- Asia Pacific

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Brazil

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Canary Islands

- Caribbean

- Central African Republic

- Central America

- Chad

- Chile

- China

- Colombia

- Congo

- Congo, Democratic Republic of

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Denmark

- Dominican Republic

- Dubai

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Estonia

- Eswatini/Swaziland

- Ethiopia

- European Union (EU)

- Fiji

- Finland

- France

- French Guiana

- Gabon

- Georgia

- Germany

- Ghana

- Global South

- Greece

- Greenland

- Grenada

- Guatemala

- Guinea

- Guyana

- Haiti

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jersey

- Jordan

- Kazakhstan

- Kenya

- Korea

- Kosovo

- Kuwait

- Laos

- Latin America

- Latvia

- Lebanon

- Liberia

- Lithuania

- Luxembourg

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Mauritania

- Mauritius

- Mexico

- Middle East

- Moldova

- Monaco

- Mongolia

- Morocco

- Mozambique

- Myanmar/Burma

- Namibia

- Nepal

- Netherlands

- New Guinea

- New Zealand

- Nicaragua

- Niger

- Nigeria

- North Africa

- North America

- North Korea

- Northern Ireland

- Norway

- Oman

- Pakistan

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Poland

- Portugal

- Qatar

- Republic of

- Romania

- Russia

- Rwanda

- Saudi Arabia

- Scotland

- Senegal

- Serbia

- Sierra Leone

- Singapore

- Slovakia/Slovak Republic

- Slovenia

- Solomon Islands

- South Africa

- South America

- South Korea (Republic of Korea)

- South Sudan

- Southeast Asia

- Spain

- Sri Lanka

- Sudan

- Suriname

- Sweden

- Switzerland

- Taiwan

- Tanzania

- Thailand

- Timor-Leste

- Togo

- Trinidad and Tobago

- Tunisia

- Turkey

- Uganda

- UK (United Kingdom)

- Ukraine

- United Arab Emirates UAE

- Uruguay

- Uzbekistan

- Vatican

- Venezuela

- Vietnam

- Wales

- Zambia

- Zanzibar

- Zimbabwe

- Marine/Boat Bio and Renewable Fuel/MGO/MDO/SMF

- Marketing/Market Forces and Sales

- Opinions

- Organizations

- Original Writing, Opinions Advanced Biofuels USA

- Policy

- Presentations

- Biofuels Digest Conferences

- DOE Conferences

- Bioeconomy 2017

- Bioenergy2015

- Biomass2008

- Biomass2009

- Biomass2010

- Biomass2011

- Biomass2012

- Biomass2013

- Biomass2014

- DOE Project Peer Review

- Other Conferences/Events

- R & D Focus

- Carbon Capture/Storage/Use

- Co-Products

- Feedstock

- Logistics

- Performance

- Process

- Vehicle/Engine/Motor/Aircraft/Boiler/Ship

- Yeast

- Railroad/Train/Locomotive Fuel

- Resources

- Books Web Sites etc

- Business

- Definition of Advanced Biofuels

- Find Stuff

- Government Resources

- Scientific Resources

- Technical Resources

- Tools/Decision-Making

- Rocket/Missile Fuel

- Sponsors

- States

- Alabama

- Alaska

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Hawai'i

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Kentucky

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Midwest

- Minnesota

- Mississippi

- Missouri

- Montana

- Native American tribal nation lands

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Puerto Rico

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- Washington DC

- West Coast

- West Virginia

- Wisconsin

- Wyoming

- Sustainability

- Uncategorized

- What You Can Do

tags

© 2008-2023 Copyright Advanced BioFuels USA. All Rights reserved.

.jpg)

0 COMMENTS

Leave A Comment

Your Email Address wiil not be Published. Required Field Are marked*