(U.S. Department of Energy) AREA OF INTEREST 4 — ADVANCED AIR SEPARATION FOR LOW-COST H2 PRODUCTION VIA MODULAR GASIFICATION

An Advanced Modular Redox Air Separation System for Cost-Effective, Net-Zero Hydrogen Production — North Carolina State University (Raleigh, North Carolina) intends to develop a redox-based, radically engineered modular air separation unit (REM-ASU) with significant reductions in capital cost and energy consumption for oxygen generation when compared to state-of-the-art air separation technologies. The team proposes to: (1) develop advanced steam-resistant oxygen sorbents with greater than 2 wt.% oxygen capacity and high activity for efficient oxygen generation without a vacuum desorption step; (2) demonstrate the REM-ASU system in a 20 kilogram per day testbed to validate the sorbent robustness and process performance; and (3) design the REM-ASU for integration with a 5-10 megawatt modular biomass gasifier with greater than 35% energy and cost reduction for greater than 98% oxygen generation compared to conventional ASUs.

DOE Funding: $1,249,960

Non-DOE Funding: $313,051

Total Value: $1,563,011

Optimization and Scale-up of Molecular-Sieve Membranes with Record Air Separation Performance — Osmoses Inc. (Cambridge, Massachusetts) plans to develop a novel membrane system from Osmoses’ proprietary polymer composition that can produce enriched oxygen from air for integration into modular gasification systems for low-cost hydrogen production. In addition to helping the nation meet ambitious carbon-neutral goals, the development and implementation of the proposed technology can help reduce the cost of and emissions from hydrogen production to mitigate the effects of climate change while creating new jobs and revitalizing our economy. By addressing a global challenge that disproportionately affects disadvantaged communities, the proposed project could have a positive impact on these communities.

DOE Funding: $1,249,997

Non-DOE Funding: $312,516

Total Value: $1,562,513

Oxygen Integrated Unit for Modular Biomass Conversion to Hydrogen— Palo Alto Research Center Inc. (Palo Alto, California), in collaboration with SIMACRO and PCI Gases, intends to develop a fast and high-capacity reversible oxygen sorbent that enables an Oxygen Integrated Unit for Modular Biomass Conversion to Hydrogen. If successful, this project will demonstrate the potential for a small-scale, modular ASU to produce clean, carbon-free energy from local biomass, providing communities with an alternative to trucks or pipelines transferring hydrogen. This success would also provide a route to fuel diversification and energy resiliency and bring the clean energy economy and jobs to rural and historically disadvantaged communities.

DOE Funding: $1,249,999

Non-DOE Funding: $312,500

Total Value: $1,562,499

Electrochemically Mediated Air Separation Modules — Raytheon Technologies Research Center (East Hartford, Connecticut), in collaboration with the Massachusetts Institute of Technology, the University of California Irvine, and the University of California Davis, plans to research, develop, and demonstrate a cost-effective, energy-efficient, clean, and scalable process for separating oxygen from air that relies on soluble redox species to capture oxygen and release it into a greater than 99% pure oxygen stream. The project will define key performance metrics for candidate electrochemically activated oxygen capture molecules, computationally assess approximately 106 transition metals complexes against these metrics, provide fundamental experimental data on a subset of materials, generate proof-of-concept subscale reactor data on at least one material set, provide design concepts appropriate for scale-up, and perform techno-economic analyses to assess the status and potential of this technology compared to conventional approaches to air separation.

DOE Funding: $1,249,958

Non-DOE Funding: $312,490

Total Value: $1,562,448

Carbon Molecular Sieve Membranes with Hierarchical Chemistries and Structures for O2/N2 Separation — State University of New York on behalf of University at Buffalo (Amherst, New York) intends to develop carbon molecular sieve hollow fiber composite membranes with hierarchical chemistries and structures for oxygen production from the air, enabling low-cost modular hydrogen production from biomasses or wastes. The team intends to address the requirement of advancing modular air separation to support modular gasification-based hydrogen production. If successfully developed, the technology would produce oxygen at a lower cost than cryogenic-based air separation at small scales and benefit small modular energy systems. This would also drive a reduction in carbon dioxide emissions and spur economic growth and domestic job creation.

DOE Funding: $1,250,000

Non-DOE Funding: $500,000

Total Value: $1,750,000

High Purity Oxygen Generation through Modular Structured RPSA — Susteon Inc. (Cary, North Carolina) plans to develop a process that produces high-purity oxygen from air at significantly lower cost than state-of-the-art commercial technologies. The proposed process technology can produce oxygen with purity greater than 95% and power consumption less than 230 kilowatt hours per ton of oxygen — using only 11.5 megawatt hours to form 50 metric tons of oxygen. The team plans to demonstrate continuous oxygen production at 10 kg per day; scale up fiber adsorbent materials for rapid pressure swing adsorption module fabrication; complete more than 100 hours of process cyclic testing, including mild pressured-adsorption followed by light vacuum-regeneration, to prove multicycle stability with low energy requirement. Additionally, the awardee intends to perform a high-fidelity techno-economic analysis and life-cycle analysis to develop a technology commercialization plan, which would involve obtaining an accurate price estimate for the high-purity oxygen for related biomass gasification.

DOE Funding: $1,250,000

Non-DOE Funding: $312,500

Total Value: $1,562,500

Advanced Air Separation Unit (ASU) for Low-Cost H2 Production Via Modular Gasification — TDA Research Inc. (Wheat Ridge, Colorado) intends to develop a modular, sorbent-based air separation unit (ASU) for oxygen production to support low-cost hydrogen production from gasification of biomass and/or wastes. The team intends to demonstrate high-purity (greater than 98% by volume, preferably above 99.5% by volume) oxygen generation from ambient air using a process that is more compact, more affordable, and more efficient than comparable cryogenic-based ASUs. The new oxygen production system will be sized to support 5-50 megawatt gasification systems (30-300 tonne per day of oxygen flow) for zero-carbon hydrogen production — a scale where the modular sorbent-based system provides significant capital and operating cost reductions compared with commercial/conventional cryogenic distillation-based oxygen generation technologies.

DOE Funding: $1,250,000

Non-DOE Funding: $312,500

Total Value: $1,562,500

AREA OF INTEREST 14a — METHANE PYROLYSIS/DECOMPOSITION, IN SITU CONVERSION, OR CYCLICAL CHEMICAL LOOPING REFORMING

Bench-Scale Testing and Development of Fixed Bed Chemical Looping Reactor for Hydrogen Generation from Natural Gas with CO2 Capture — The Ohio State University (Columbus, Ohio), teaming with Babcock and Wilcox, plans to develop a fixed bed chemical looping process to produce hydrogen from natural gas with in-situ carbon dioxide capture using an iron-based mixed metal oxide composite (MMOC) with the overall goal to validate and scale up the MMOC-based fixed bed technology for hydrogen production and analyze its techno-economic impact. The fixed bed chemical looping system has been designed to operate in three reaction modes that can occur simultaneously for continuous hydrogen production: natural gas utilization through the reduction of MMOC, steam oxidation and air regeneration.

DOE Funding: $1,499,238

Non-DOE Funding: $375,000

Total Value: $1,874,238

Lower-Cost, CO2-Free H2 Production via CH4 Pyrolysis in Molten Tin — Massachusetts Institute of Technology (Cambridge, Massachusetts) researchers intend to employ a novel methane pyrolysis approach to produce low-cost hydrogen that does not producecarbon dioxide as a byproduct. The approach leverages a key technological innovation: the ability to pump and contain liquid metals such as liquid tin at temperatures greater than 1400 °C. Since tin is inert with respect to both carbon and hydrogen, it can be used as a heat transfer fluid in a high-temperature bubble column reactor that does not need a catalyst, since it can operate at high enough temperatures to ensure complete conversion (i.e., approximately 1400 °C). The liquid tin can be used to facilitate continuous removal of the solid carbon byproduct and can be used to facilitate an innovative heat recovery technique that renders the entire process energy efficient.

DOE Funding: $1,500,000

Non-DOE Funding: $375,048

Total Value: $1,875,048

Thermo-Catalytic Co-Production of Hydrogen and High-Value Carbon Products from Natural Gas Using Structured Materials — Susteon Inc. (Carey, North Carolina), in collaboration with Stanford University and Rice University, intends to develop and demonstrate a novel thermocatalytic methane pyrolysis process that utilizes a structured catalyst to produce high-value carbon and hydrogen. The structured catalyst consists of a supported active metal and provides the ability to utilize low-carbon renewable electricity to supply the endothermic heat required for methane pyrolysis. Extensive experimental work has been performed to identify a catalyst composition and process design capable of achieving greater than 90% single pass conversion of methane into hydrogen at temperatures below 850 °C, which significantly lowers the downstream purification costs. The process simultaneously produces high-quality carbon, primarily carbon nanotubes, which sequesters the carbon as a solid, avoids gaseous emissions, and creates a high-value, salable product. The process enables efficient separation of solid carbon particles, which is a key challenge of methane pyrolysis, and can help significantly offset the cost of hydrogen production.

DOE Funding: $1,500,000

Non-DOE Funding: $375,000

Total Value: $1,875,000

Direct Solar Self-Catalyzing Pyrolysis of Natural Gas to Hydrogen and High-Quality Graphite — University of California, Los Angeles (UCLA) (Los Angeles, California), in collaboration with the Southwest Solar Technology LLC and SolGrapH Inc., plans to advance a novel technology discovered by UCLA researchers that uses concentrated solar energy to convert methane into green hydrogen and a high-value form of solid carbon. In lieu of ventingcarbon dioxide to the atmosphere, the process transforms natural gas-derived carbon into stable graphitic carbon that can be used to produce batteries or other high-value end products. This first-of-its-kind process releases zero direct carbon dioxide emissions by capturing the carbon that is typically released and sequester it into a valuable commodity for use in the renewable energy ecosystem. The team will conduct a series of scale-up experiments to achieve high yields of hydrogen and graphitic carbon in a representative solar environment with 40–50 kilowatt insolation to produce greater than 5 kilograms of hydrogen per day. UCLA’s team will quantify the benefits and outcomes of these efforts through a combination of detailed instrumentation and internal as well as third-party verification.

DOE Funding: $1,461,772

Non-DOE Funding: $377,848

Total Value: $1,839,620

AREA OF INTEREST 14b — HYDROGEN PRODUCTION FROM PRODUCED WATER

HALO: Hydrogen-Recovery Using an AI-Arc-Plasma Learning Operational System for Produced Water — Oceanit Laboratories, Inc. (Honolulu, Hawaii) plans to develop a modular, mobile hydrogen production system that uses plasma technology to provide the operational flexibility needed to dissociate toxic produced water into valuable end products. The HALO (Hydrogen-recovery using AI-arc-plasma Learning Operational) system provides a modular and scalable solution to achieve the simultaneous goals of fuel recovery and disposal of toxic wastewater from oil and natural gas production. Oceanit will also apply advanced artificial intelligence to optimize the hydrogen production process to increase efficiency and reduce operating costs by utilizing toxic wastewater as fuel to power HALO. For this project, a pilot-scale HALO system will be designed, fabricated, and integrated into an active wastewater treatment facility unit to measure its performance and identify other valuable end products.

DOE Funding: $5,000,000

Non-DOE Funding: $5,000,000

Total Value: $10,000,000

Integration of Produced Water Thermal Desalination and Steam Methane Reforming (SMR) for Efficient Hydrogen Production — University of Wyoming (Laramie, Wyoming), with partners Los Alamos National Laboratory and Engineering, Procurement & Construction LLC, plan to demonstrate hydrogen production using water produced during oil and gas extraction by integrating supercritical water desalination and oxidation (SCWDO) with steam methane reforming (SMR). SCWDO uses heat to remove salts, metals and organic molecules from water and SMR then combines this pure water with methane to produce hydrogen. The team has previously shown that the heat intensive SCWDO process can be coupled to the front of an SMR process. Both SCWDO and SMR are hot processes, and the project will show how they can be integrated at large scale to conserve heat energy, enabling field demonstration of a 15% cost reduction over existing SMR technologies at approximately one ton of hydrogen per day.

DOE Funding: $4,997,749

Non-DOE Funding: $4,999,387

Total Value: $9,997,136

AREA OF INTEREST 15 — TECHNOLOGIES FOR ENABLING THE SAFE AND EFFICIENT TRANSPORTATION OF HYDROGEN WITHIN THE U.S. NATURAL GAS PIPELINE SYSTEM

Assessment of Toughness in H-Containing Blended Gas Environments in High Strength Pipeline Steels — Colorado School of Mines (Golden, Colorado) intends to determine the influence of microstructure on steel lined pipe mechanical property qualification metrics for blended gas environments containing hydrogen. The investigation will be performed on steels with a range of strength levels (e.g., X52 to X80 steels) to inform potential modification of these standards to incorporate use of higher strength grades at higher hydrogen pressures. If successful, this modification would enable significant cost savings and increase hydrogen carrying capacity while maintaining reliability. The project could also produce a ranked list of critical alloy and microstructure features that correlate to enhanced hydrogen embrittlement resistance in pipeline steels at strength levels up to those comparable to an X80 pipeline steel.

DOE Funding: $1,500,000

Non-DOE Funding: $375,000

Total Value: $1,875,000

Technologies for Enabling the Safe and Efficient Transportation of Hydrogen within the U.S. Natural Gas Pipeline System — Southwest Research Institute (San Antonio, Texas), the 20 natural gas pipeline operating companies, and 50 engineering and equipment manufacturing companies that are members of the Gas Machinery Research Council (GMRC) plan to develop and demonstrate a full-scale compression system blending hydrogen and natural gas through modification and operation of an existing reciprocating compressor piping loop. This effort aims to advance multiple technologies enabling near-term, safe transportation of hydrogen within the U.S. natural gas pipeline system by adapting and operating the closed-loop compression facility with hydrogen-natural gas blends up to 20% hydrogen by volume. If successful, this project will enable safe and efficient compression of hydrogen-natural gas blends by de-risking the application and adaptation of these components for hydrogen blending through detailed evaluation, modification, commissioning, and operation at full-scale conditions, including the design, construction, and integration of a blending skid and testing of a hydrogen separation system for high value end uses.

DOE Funding: $1,500,000

Non-DOE Funding: $375,000

Total Value: $1,875,000

AREA OF INTEREST 16 — FUNDAMENTAL RESEARCH TO ENABLE HIGH VOLUME, LONG-TERM SUBSURFACE HYDROGEN STORAGE

Developing & Investigating Subsurface Storage Potential and Technical Challenges for Hydrogen — Institute of Gas Technology dba GTI Energy (Des Plaines, Illinois) intends to determine the feasibility of using Oklahoma’s vast depleted oil and gas reservoirs to enable the transition to a carbon free energy infrastructure. A successful outcome of the project would provide: an affirmation of underground hydrogen storage feasibility in the depleted oil and gas reservoirs and potentially feasible volumes, timelines, and operational pathways; clarification of projects risks, mitigation/monitoring planning, hydrogen source and transport planning; analysis of contractual and regulatory requirements, technical and economic feasibility assessment, and field deployment planning; and an evaluation of commercial-scale storage feasibility in a geographic region and a geologic setting not previously achieved.

DOE Funding: $1,400,000

Non-DOE Funding: $350,000

Total Value: $1,750,000

Williston Basin Resource Study for Commercial-Scale Subsurface Hydrogen Storage — University of North Dakota Energy and Environmental Research Center (Grand Forks, North Dakota) plans to support the future commercialization of hydrogen generation, storage, and use by assessing the potential for high-volume, secure subsurface hydrogen storage with high recovery from geologic complexes of the North Dakota portion of the Williston Basin. The team plans to assess saline, depleted oil and gas, and salt formations for hydrogen storage suitability; characterize and assess the effects of long-term hydrogen storage use and exposure on formation fluids, storage and confining unit rocks, and wellbore materials; and conduct a basin-wide estimate of geologic hydrogen storage potential, including factors that will inform storage and recovery performance. This project will build upon proof-of-concept validation regarding fundamental research to determine the hydrogen storage resource potential of the Williston Basin’s geologic formations and progress through the proposed assessment to support potential field-scale development in subsequent research phases.

DOE Funding: $1,500,000

Non-DOE Funding: $375,000

Total Value: $1,875,000

Hydrogen Storage in Salt Caverns in the Permian Basin: Seal Integrity Evaluation and Field Test — University of Texas at Austin (Austin, Texas) intends to determine the hydrogen sealing capacity of storage caverns in bedded salt within the Salado Formation in the Permian Basin, a major energy hub in the United States. The research project will investigate the physical properties of salt rocks in the presence of hydrogen, effects of long-term hydrogen exposure on rocks and cement, and the impact of coupled geochemically and microbially induced processes that might alter initial properties. The research approach combines advanced experimental techniques and numerical simulation for multiphase fluid flow and geomechanics from the pore to the core scale, geophysical methods for vertical heterogeneity characterization at the meso-scale, and validation through a full-scale test with a hydrogen injection borehole and monitoring wells in DOE’s Waste Isolation Pilot Plant in New Mexico.

DOE Funding: $1,483,488

Non-DOE Funding: $370,873

Total Value: $1,854,361

Assessment of Subsurface Hydrogen Storage in Depleted Gas Fields of Appalachia — Virginia Polytechnic Institute and State University (Blacksburg, Virginia) plans to establish the subsurface hydrogen storage potential in the depleted gas fields of Appalachia, which include Berea, Big Lime, and fractured Marcellus. Subsurface hydrogen storage in depleted gas fields will provide large volumetric storage capacities for hydrogen, without the need for massive surface storage infrastructures. Such operations will allow clean energy to be made available, especially during periods of low-supply and high-demand. Developing this technology could increase energy democracy, provide access to low-cost capital, increase clean energy jobs, and decrease energy burden, especially in the disadvantaged Appalachian communities.

DOE Funding: $1,499,999

Non-DOE Funding: $375,000

Total Value: $1,874,999

- Virginia Tech awarded $1.5M for hydrogen storage project; (Cardinal News)

- Hydrogen: The Key to Clean Energy? Let’s Scale Up Storage First (GTI Energy/Medium)

- NREL Selected as Part of $1.6M in Federal Funding To Explore Potential of Geologic Hydrogen -- NREL One of 16 Teams Selected by DOE’s Advanced Research Projects Agency-Energy (National Renewable Energy Laboratory)

- Bill Gates-backed startup says a global gold rush for buried hydrogen is picking up momentum (CNBC)

Excerpt from National Renewable Energy Laboratory:

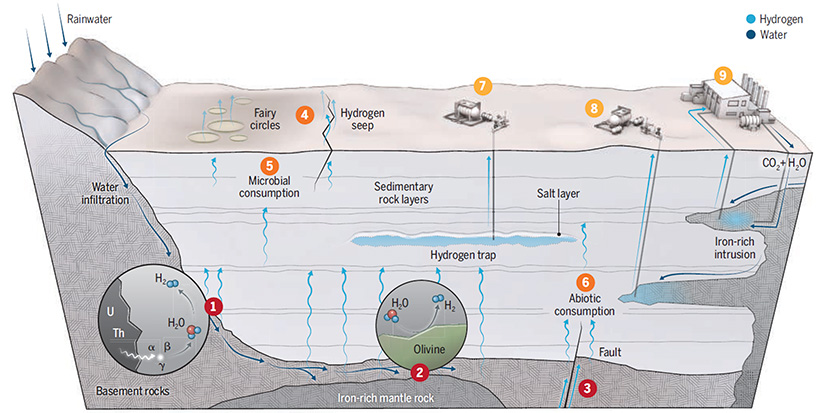

NREL is working with partners to explore the potential of geologic hydrogen. Graphic from Science

The National Renewable Energy Laboratory (NREL) was recently selected as one of 16 teams to research enhanced production of geologic hydrogen by the U.S. Department of Energy (DOE) Advanced Research Projects Agency-Energy (ARPA-E) program.

Led by Texas Tech University with partners from NREL, Lawrence Berkeley National Laboratory, Rio Tinto, and Lavoisier H2 Geoconsult, this project aims to stimulate hydrogen production from iron-rich mafic and ultramafic rocks via chemical, mechanical, and biological processes.

Changing the Game With Geologic Hydrogen

Geologic hydrogen is currently a poorly understood but potentially groundbreaking energy resource involving certain types of rocks and subsurface environments that produce natural hydrogen. ARPA-E is leading first-of-its-kind federal funding efforts to evaluate ways to stimulate hydrogen production (enhance or increase the natural rates) from geologic resources. Clean hydrogen, including naturally occurring subsurface hydrogen, can sustainably reduce harmful emissions from some of the most energy-intensive sectors of the economy, such as chemical and industrial processes and heavy-duty transportation.

The project will produce valuable scientific research to understand the opportunities this resource presents via a first-of-its-kind research grant on geologic hydrogen stimulation technologies.

"Natural hydrogen production is important because current methods for producing hydrogen are energy intensive, with hydrogen needing to be derived from other sources, like water or methane," said Dayo Akindipe, an NREL research scientist in the Center for Energy Conversion and Storage Systems. "This new process intends to accelerate the production of natural hydrogen by applying multiple stimulation methods to produce hydrogen that can be used for transportation, chemical and industrial processes, and other applications. This research will allow NREL to enable another clean hydrogen pathway."

Led by Akindipe, NREL will support this new project by implementing a microcosm experiment to characterize the rock, water, and hydrogen system. NREL researchers Katherine Chou and Jianping Yu will look at ways to inhibit the microbial uptake of the produced hydrogen and see how biocatalysts can help to increase the rate of hydrogen production. NREL's team will also assist in developing tech-to-market efforts once they have established the viability of the geologic hydrogen system.

Transforming Energy

Akindipe, who has a background in chemical and petroleum engineering, began his career working in the oil and gas industry before coming to NREL. For him, this project merges both his experience and his passion for sustainable energy.

"This ties into my own personal energy transition," he said. "I became even more active in the space of geologic hydrogen because I saw it was a niche area—not just at NREL, but for the entire country. It's an area that the U.S. can tap into that will positively transform the energy space and society."

The funding is part of ARPA-E's Exploratory Topics related to geologic hydrogen, which aim to explore early-stage research and development to advance low-cost, low-emissions hydrogen. This is the first time that the U.S. government has competitively selected teams to research this kind of technology. This energy resource would potentially produce no carbon emissions when burned or used in a fuel cell and will support efforts to reduce costs and enable commercial-scale deployment of clean hydrogen.

The teams selected will explore early-stage research and development to advance low-cost, low-emissions hydrogen, which will help create good-paying jobs and new economic opportunities in communities across the nation while also helping meet climate and decarbonization goals.

"This project is going to tell us a couple of things," Akindipe said. "Firstly, is geologic hydrogen production possible at scale? Secondly, will it be feasible economically and in terms of life cycle emissions? These are the questions this project will answer."

For NREL, this project establishes a first-of-its-kind research in geologic hydrogen—adding a new path toward clean and low-cost hydrogen.

Learn more about NREL geothermal and hydrogen research, as well as the ARPA-E program.

Nearly 55,000 articles in our online library!

Use the categories and tags listed below to access the nearly 50,000 articles indexed on this website.

Advanced Biofuels USA Policy Statements and Handouts!

- For Kids: Carbon Cycle Puzzle Page

- Why Ethanol? Why E85?

- Just A Minute 3-5 Minute Educational Videos

- 30/30 Online Presentations

- “Disappearing” Carbon Tax for Non-Renewable Fuels

- What’s the Difference between Biodiesel and Renewable (Green) Diesel? 2020 revision

- How to De-Fossilize Your Fleet: Suggestions for Fleet Managers Working on Sustainability Programs

- New Engine Technologies Could Produce Similar Mileage for All Ethanol Fuel Mixtures

- Action Plan for a Sustainable Advanced Biofuel Economy

- The Interaction of the Clean Air Act, California’s CAA Waiver, Corporate Average Fuel Economy Standards, Renewable Fuel Standards and California’s Low Carbon Fuel Standard

- Latest Data on Fuel Mileage and GHG Benefits of E30

- What Can I Do?

Donate

DonateARCHIVES

- February 2026

- January 2026

- December 2025

- November 2025

- October 2025

- September 2025

- August 2025

- July 2025

- June 2025

- May 2025

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- September 2009

- August 2009

- July 2009

- June 2009

- May 2009

- April 2009

- March 2009

- February 2009

- January 2009

- December 2008

- November 2008

- October 2008

- September 2008

- August 2008

- July 2008

- June 2008

- May 2008

- April 2008

- March 2008

- February 2008

- January 2008

- December 2007

- November 2007

- October 2007

- September 2007

- August 2007

- June 2007

- February 2007

- January 2007

- October 2006

- April 2006

- January 2006

- April 2005

- December 2004

- November 2004

- December 1987

CATEGORIES

- About Us

- Advanced Biofuels Call to Action

- Aviation Fuel/Sustainable Aviation Fuel (SAF)

- BioChemicals/Renewable Chemicals

- BioRefineries/Renewable Fuel Production

- Business News/Analysis

- Cooking Fuel

- Education

- 30/30 Online Presentations

- Competitions, Contests

- Earth Day 2021

- Earth Day 2022

- Earth Day 2023

- Earth Day 2024

- Earth Day 2025

- Executive Training

- Featured Study Programs

- Instagram TikTok Short Videos

- Internships

- Just a Minute

- K-12 Activities

- Mechanics training

- Online Courses

- Podcasts

- Scholarships/Fellowships

- Teacher Resources

- Technical Training

- Technician Training

- University/College Programs

- Events

- Coming Events

- Completed Events

- More Coming Events

- Requests for Speakers, Presentations, Posters

- Requests for Speakers, Presentations, Posters Completed

- Webinars/Online

- Webinars/Online Completed; often available on-demand

- Federal Agency/Executive Branch

- Agency for International Development (USAID)

- Agriculture (USDA)

- Commerce Department

- Commodity Futures Trading Commission

- Congressional Budget Office

- Defense (DOD)

- Air Force

- Army

- DARPA (Defense Advance Research Projects Agency)

- Defense Logistics Agency

- Marines

- Navy

- Education Department

- Energy (DOE)

- Environmental Protection Agency

- Federal Energy Regulatory Commission (FERC)

- Federal Reserve System

- Federal Trade Commission

- Food and Drug Administration

- General Services Administration

- Government Accountability Office (GAO)

- Health and Human Services (HHS)

- Homeland Security

- Housing and Urban Development (HUD)

- Interior Department

- International Trade Commission

- Joint Office of Energy and Transportation

- Justice (DOJ)

- Labor Department

- National Academies of Sciences Engineering Medicine

- National Aeronautics and Space Administration

- National Oceanic and Atmospheric Administration

- National Research Council

- National Science Foundation

- National Transportation Safety Board (NTSB)

- Occupational Safety and Health Administration

- Overseas Private Investment Corporation

- Patent and Trademark Office

- Securities and Exchange Commission

- State Department

- Surface Transportation Board

- Transportation (DOT)

- Federal Aviation Administration

- National Highway Traffic Safety Administration (NHTSA)

- Pipeline and Hazardous Materials Safety Admin (PHMSA)

- Treasury Department

- U.S. Trade Representative (USTR)

- White House

- Federal Legislation

- Federal Litigation

- Federal Regulation

- Feedstocks

- Agriculture/Food Processing Residues nonfield crop

- Alcohol/Ethanol/Isobutanol

- Algae/Other Aquatic Organisms/Seaweed

- Atmosphere

- Carbon Dioxide (CO2)

- Field/Orchard/Plantation Crops/Residues

- Forestry/Wood/Residues/Waste

- hydrogen

- Manure

- Methane/Biogas

- methanol/bio-/renewable methanol

- Not Agriculture

- RFNBO (Renewable Fuels of Non-Biological Origin)

- Seawater

- Sugars

- water

- Funding/Financing/Investing

- grants

- Green Jobs

- Green Racing

- Health Concerns/Benefits

- Heating Oil/Fuel

- History of Advanced Biofuels

- Infrastructure

- Aggregation

- Biofuels Engine Design

- Biorefinery/Fuel Production Infrastructure

- Carbon Capture/Storage/Use

- certification

- Deliver Dispense

- Farming/Growing

- Precursors/Biointermediates

- Preprocessing

- Pretreatment

- Terminals Transport Pipelines

- International

- Abu Dhabi

- Afghanistan

- Africa

- Albania

- Algeria

- Angola

- Antarctica

- Arctic

- Argentina

- Armenia

- Aruba

- Asia

- Asia Pacific

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Brazil

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Canary Islands

- Caribbean

- Central African Republic

- Central America

- Chad

- Chile

- China

- Colombia

- Congo

- Congo, Democratic Republic of

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Denmark

- Dominican Republic

- Dubai

- Ecuador

- Egypt

- El Salvador

- Equatorial Guinea

- Estonia

- Eswatini/Swaziland

- Ethiopia

- European Union (EU)

- Fiji

- Finland

- France

- French Guiana

- Gabon

- Georgia

- Germany

- Ghana

- Global South

- Greece

- Greenland

- Grenada

- Guatemala

- Guinea

- Guyana

- Haiti

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jersey

- Jordan

- Kazakhstan

- Kenya

- Korea

- Kosovo

- Kuwait

- Laos

- Latin America

- Latvia

- Lebanon

- Liberia

- Lithuania

- Luxembourg

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Mauritania

- Mauritius

- Mexico

- Middle East

- Moldova

- Monaco

- Mongolia

- Morocco

- Mozambique

- Myanmar/Burma

- Namibia

- Nepal

- Netherlands

- New Guinea

- New Zealand

- Nicaragua

- Niger

- Nigeria

- North Africa

- North America

- North Korea

- Northern Ireland

- Norway

- Oman

- Pakistan

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Poland

- Portugal

- Qatar

- Republic of

- Romania

- Russia

- Rwanda

- Saudi Arabia

- Scotland

- Senegal

- Serbia

- Sierra Leone

- Singapore

- Slovakia/Slovak Republic

- Slovenia

- Solomon Islands

- South Africa

- South America

- South Korea (Republic of Korea)

- South Sudan

- Southeast Asia

- Spain

- Sri Lanka

- Sudan

- Suriname

- Sweden

- Switzerland

- Taiwan

- Tanzania

- Thailand

- Timor-Leste

- Togo

- Trinidad and Tobago

- Tunisia

- Turkey

- Uganda

- UK (United Kingdom)

- Ukraine

- United Arab Emirates UAE

- Uruguay

- Uzbekistan

- Vatican

- Venezuela

- Vietnam

- Wales

- Zambia

- Zanzibar

- Zimbabwe

- Marine/Boat Bio and Renewable Fuel/MGO/MDO/SMF

- Marketing/Market Forces and Sales

- Opinions

- Organizations

- Original Writing, Opinions Advanced Biofuels USA

- Policy

- Presentations

- Biofuels Digest Conferences

- DOE Conferences

- Bioeconomy 2017

- Bioenergy2015

- Biomass2008

- Biomass2009

- Biomass2010

- Biomass2011

- Biomass2012

- Biomass2013

- Biomass2014

- DOE Project Peer Review

- Other Conferences/Events

- R & D Focus

- Carbon Capture/Storage/Use

- Co-Products

- Feedstock

- Logistics

- Performance

- Process

- Vehicle/Engine/Motor/Aircraft/Boiler/Ship

- Yeast

- Railroad/Train/Locomotive Fuel

- Resources

- Books Web Sites etc

- Business

- Definition of Advanced Biofuels

- Find Stuff

- Government Resources

- Scientific Resources

- Technical Resources

- Tools/Decision-Making

- Rocket/Missile Fuel

- Sponsors

- States

- Alabama

- Alaska

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Hawai'i

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Kentucky

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Midwest

- Minnesota

- Mississippi

- Missouri

- Montana

- Native American tribal nation lands

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Puerto Rico

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- Washington DC

- West Coast

- West Virginia

- Wisconsin

- Wyoming

- Sustainability

- Uncategorized

- What You Can Do

tags

© 2008-2023 Copyright Advanced BioFuels USA. All Rights reserved.

.jpg)

Comments are closed.