by Robert E. Kozak* (Advanced Biofuels USA) Here at Advanced Biofuels USA we’ve been banging the drum for E30 for a number of years. Equal fuel mileage, better performance, you know the facts.

Well, all that time we never had a Flex Fuel car, either factory built or retrofitted.

This fall we decided to do something about that.

Our starting point was Executive Director Joanne Ivancic’s bright yellow 2002 Ford Focus ZX3 which had traveled over 110,000 miles.

If anyone knows much about the 1st generation ZX3 they’ll tell you it handles great and loves rallye type roads but is a bit of an under-achiever in the power department. Its 4 cylinder 2.0L Zetec engine has all the right specifications; dual overhead cams (DOHC), aluminum block, etc. but low-end torque and mid-range RPM horsepower both seem to be lacking. It’s especially noticeable when driving uphill. The throttle is wide-open but whatever additional fuel is supposed to be added doesn’t seem to do much. The Zetec engine was developed in Europe where the standard octane is 92. It almost seems as if when Ford recalibrated the US Zetec to run on 87 octane regular the fuel trim and ignition timing maps were not balanced between mileage and performance but instead were set to maximize fuel economy on the EPA emission/fuel mileage cycles.

Our first step toward an “E30 and Beyond Retrofit” was looking at the websites and specifications of various E85 retrofit kits.

Fuel Flex International attracted our attention with what seemed to be a simple approach – electronically modifying the fuel injection pulse signal while retaining all other aspects of the factory installed computer and engine sensors. It also seemed like an easy system to remove which would allow us to return the car to factory settings if needed.

We contacted Alex Conger at Fuel Flex and pitched him the idea of Fuel Flex providing us with a system for installation and testing. In return we’d write up our results on the Advanced Biofuels USA website for all the world to see. He said he’d think about it. A few days later he agreed. He must have a lot of confidence in his system, I thought.

We sent him photos of the fuel injector electrical connectors on the Focus and on Saturday morning, October 24th the retrofit kit arrived by US mail. Unfortunately, we had just started a major insulation/energy reduction project for our offices so the kit had to stay in the box for awhile.

Fuel Flex Retrofit Kit (Installation guide and technical manual, upgrade kit, Fuel Flex insignia, business card)

Fuel Flex Retrofit Kit (Installation guide and technical manual, upgrade kit, Fuel Flex insignia, business card)

Finally on Sunday, November 8th I started. The installation looked straight forward. The Fuel Flex package is designed to be plugged in-line to the factory delivered system.

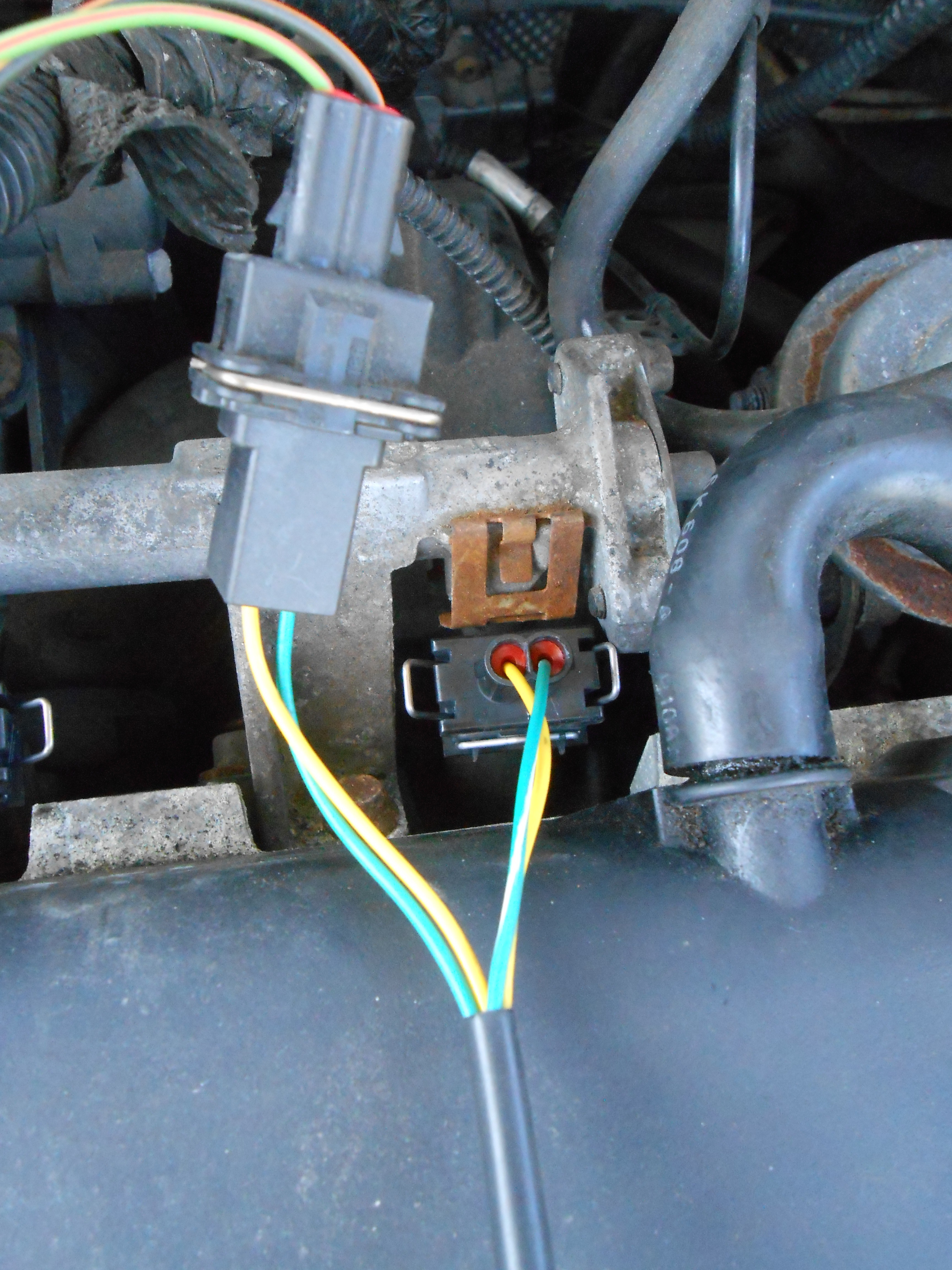

This means; 1) disconnect the current 4 fuel injector electrical connectors (one per cylinder) from the factory receptors, 2) plug the original connectors into one of the package of 4 dual Fuel Flex connectors, and 3) plug the other 4 connectors of the Fuel Flex package back into the fuel injector receptors.

However, when I disconnected the factory electrical connectors I saw the original electrical connector hardware might present a problem. Ford had installed a nice plastic box that kept the connectors and their wires organized. While I’m sure this sped up the engine assembly, the box prevented an installation of the Fuel Flex package – there simply was no room.

Since I did not want to remove or break anything on the Focus, I put everything back together and we sent photos to Alex at Fuel Flex. Fortunately he had encountered this arrangement in the past. He said the box provided no electrical functions, it just cleaned up the installation. As long as I was careful and used wire ties when needed the Fuel Flex system could be installed without the box.

Wednesday, November 11th, WWI Armistice Day, it was installed.

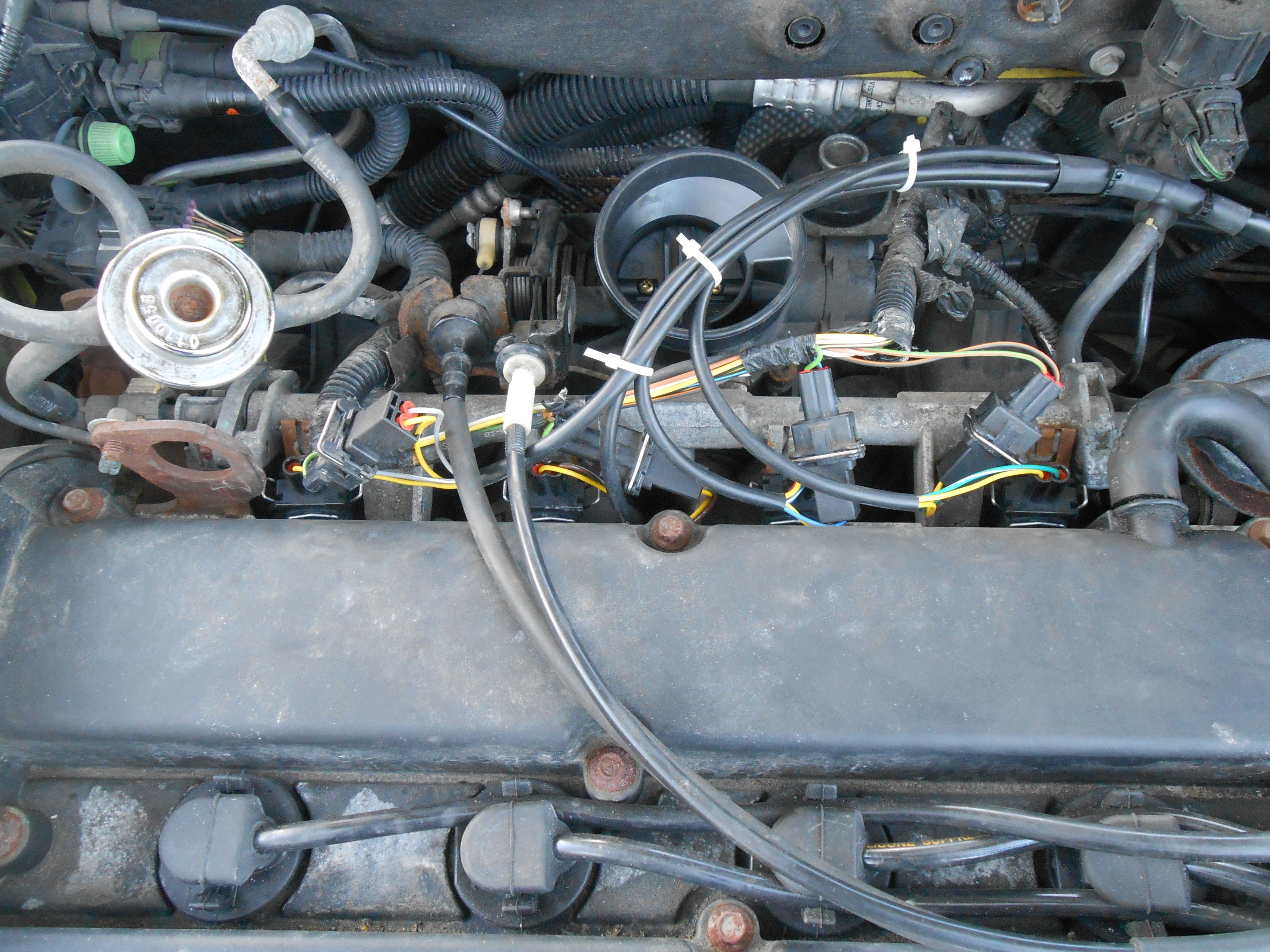

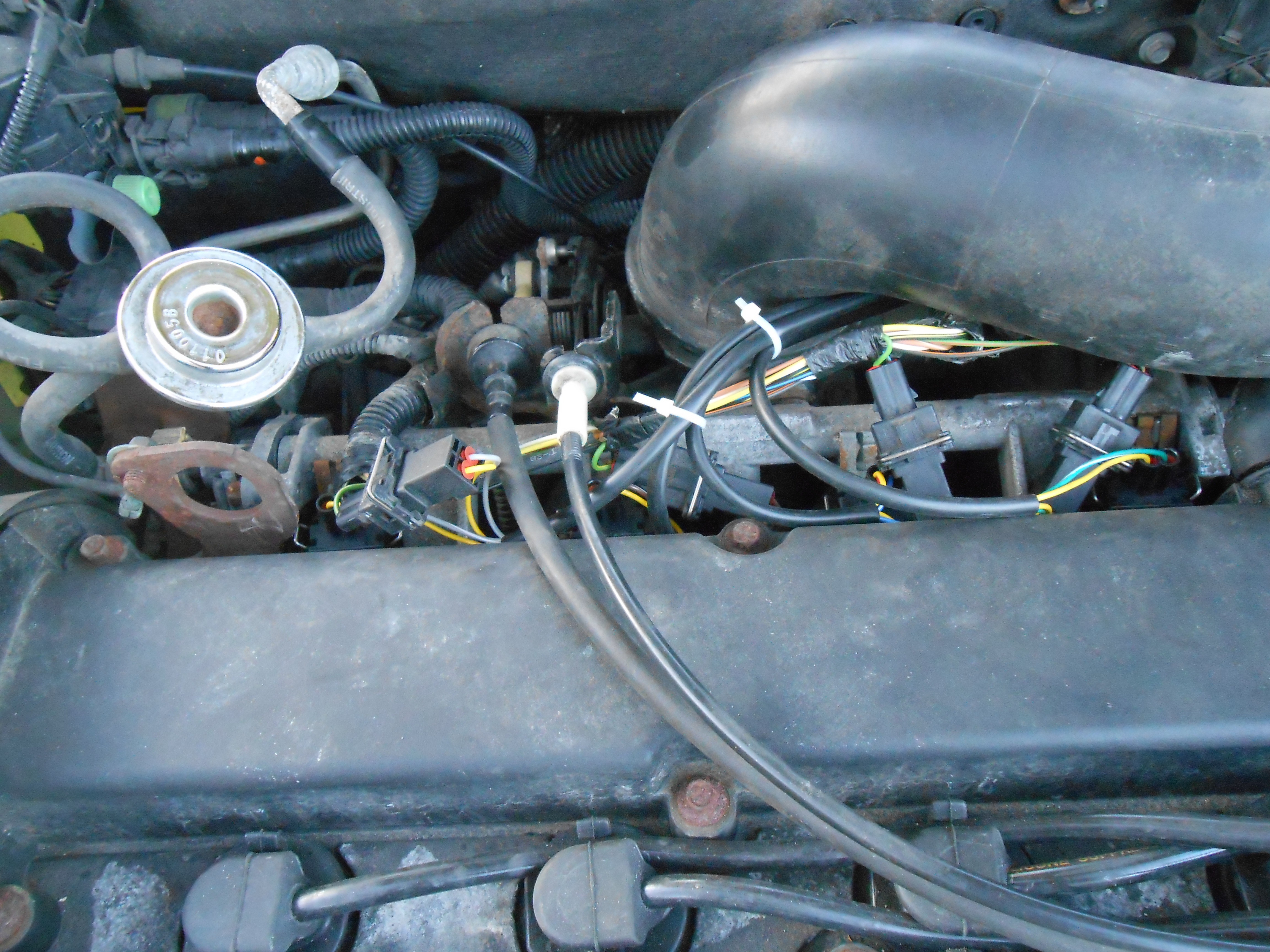

The box was removed without damage so it could be reused if needed. The in-line connectors installed easily and quickly. Removing the air intake pipe from the throttle made that job much easier.

The one issue, which took about an hour to resolve was finding a mounting spot for the Fuel Flex control box and safely mounting it. As you can see in this photo there is very little excess real estate under a Focus hood. Ford did a good job removing most unneeded space to reduce the frontal area of the ZX3. A spot was found between the battery and the right front fender. Holes were drilled and the control box mounted.

Once everything was hooked up and sufficient plastic ties were installed to keep the wiring out of trouble, it was time to reconnect the battery and fire up the engine.

It started on the first try. There was a bit of a stumble at idle, but after several restart cycles it seemed the Focus ECU and the Fuel Flex system had synced their fuel trim signals and the idle smoothed out. So far the Check Engine light DID NOT come on. That was a good sign.

The next step was what this whole project was about. Could the Focus run on an ethanol concentration higher than 10 percent? We backed out of the driveway. The odometer read 110,998. Next stop, an E85 pump.

Frederick, Maryland is fortunate to have an E85 equipped station. Please read Joanne’s article about our fueling adventures!

According to the Excel spreadsheet I set up for this project, we put in 3.5 gallons of E85. This meant the resulting ethanol content in the tank was about 38%. We headed west on US40, The National Road.

No stumbles, engine still smooth, NO Check Engine Light. After about 15-20 miles, which seemed to be enough time for the E38 mixture to be flowing through the fuel injectors, I decided to see how the Focus would climb. It seemed like an improvement. When I opened the throttle, I felt a little shove back into the seat. She was accelerating. A little more throttle, a little more power. Now that felt good. Before contributing to the Maryland State Police coffers I backed off and we returned home.

We started piling up the miles. I wanted to get several hundred on the new ethanol mixtures before writing anything. Also, I wanted to accumulate at least 200 miles before I made one other change – a new fuel filter. Ethanol, besides being a good fuel, is also a good solvent. I wanted the 30%+ ethanol mixture to clean out the fuel tank of any residuals that might have accumulated since the fuel pump was replaced about 30,000 miles ago. Also, I wanted to replace it before we went to Cleveland for Thanksgiving.

Note to anyone contemplating spending a pleasant afternoon replacing a Focus fuel filter. Let someone else do it. Remember what I said about the lack of room under the Focus hood? The same can be said for the space around the gas tank. While it was colder out than it looked and it did get dark, the car had a new fuel filter. Even better, I had installed one with the Flex-Fuel part number!

It’s now December 8th 2016. We have over 1,300 miles running on E30+ mixtures. We have purchased 26.6 gallons of E85 and have displaced about 63% of a barrel of oil. What do I think?

One. It’s been hard to keep the mixture around E30. When I start pumping in the E85 it’s hard to stop. While this project was supposed to be an E30 experiment, I’m guilty of putting in that good ethanol until the mixture is around 40%. Oh and by the way, except for the Pennsylvania Turnpike, it’s been cheaper.

Two. Performance. I haven’t had a chance to compare OBD (On-Board Diagnostic) outputs for timing, O2 sensors, fuel mapping, etc., yet for E10 and E30, nor have I gotten the car on a dyno so all I have are observations. But, having now gone both directions on the Pennsylvania Turnpike, a road well traveled in the past with this car, it seemed to go up hills much easier and faster. On the eastbound return trip there was rain, fog, and many trucks. This resulted in many uphill braking and acceleration events to get around the truck traffic.

Pretty Baby (her new name because of her many trips to New Orleans and, well she looks cute and happy with her new fuel) hauled the mail quite well. No need to plan movements ahead of time. Using the throttle produced immediate results.

My perception is that the increased octane of the E30+ mixture is allowing the car’s computer to delay spark ignition just enough (about a millionth of a second) to slightly increase the compression ratio and produce more torque. This is something I want to explore with the OBD read-outs.

One other note on performance. Pretty Baby got two new Tiger Paw GTZ AS 20550ZR16s in Cleveland. Yes, those are not “touring” tires.

Three. Mileage. See above, performance. Also, a left front wheel bearing kept getting louder. It’s now replaced. The friction from the bad one probably didn’t help mileage either.

Coming back from Cleveland with a new bearing and new tires in the rain and fog we had about a 42% ethanol mixture. Mileage was down from previous E10 runs by about 10% which is in keeping with most data. We are now running about a 32% ethanol mixture. This tank of fuel should give us some decent data.

Four. Next Steps. We will be tracking mileage more closely now that the shake-down phase of the project is over. If we can force ourselves to run on E10 we’ll also try some comparison runs. We’ll also be hooking-up our OBD system software to look at engine setting for different ethanol values. Keep your eyes open for future reports.

Five. Am I Glad We Did It? Yes. There’s nothing like using renewable, low GHG fuel is there? Also having the extra performance doesn’t hurt.

Six. Would I Recommend Converting to E30+ to Others? Yes. If you have a vehicle out of warranty that has good quality components and you want to do something for renewable fuels and the planet I’d highly recommend it. Get in touch with Alex Conger at Fuel Flex International or other reputable people. Do it as soon as you can!

Follow this series of articles about installing and using an E85 retrofit kit via tags Flex Fuel Vehicles (FFV), E85 conversion kit and What You Can Do.

*Robert E. (Bob) Kozak is the founder of Atlantic Biomass, LLC, and a co-founder of Advanced Biofuels USA. Having worked for about 40 years in the transportation, energy, environmental, and government relations industries and in enzyme development, he serves as a fuels/engines and policy expert for Advanced Biofuels USA. He can be reached at atlanticbiomass @ aol.com

Nearly 55,000 articles in our online library!

Use the categories and tags listed below to access the nearly 50,000 articles indexed on this website.

Advanced Biofuels USA Policy Statements and Handouts!

- For Kids: Carbon Cycle Puzzle Page

- Why Ethanol? Why E85?

- Just A Minute 3-5 Minute Educational Videos

- 30/30 Online Presentations

- “Disappearing” Carbon Tax for Non-Renewable Fuels

- What’s the Difference between Biodiesel and Renewable (Green) Diesel? 2020 revision

- How to De-Fossilize Your Fleet: Suggestions for Fleet Managers Working on Sustainability Programs

- New Engine Technologies Could Produce Similar Mileage for All Ethanol Fuel Mixtures

- Action Plan for a Sustainable Advanced Biofuel Economy

- The Interaction of the Clean Air Act, California’s CAA Waiver, Corporate Average Fuel Economy Standards, Renewable Fuel Standards and California’s Low Carbon Fuel Standard

- Latest Data on Fuel Mileage and GHG Benefits of E30

- What Can I Do?

Donate

DonateARCHIVES

- July 2025

- June 2025

- May 2025

- April 2025

- March 2025

- February 2025

- January 2025

- December 2024

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- February 2024

- January 2024

- December 2023

- November 2023

- October 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- October 2022

- September 2022

- August 2022

- July 2022

- June 2022

- May 2022

- April 2022

- March 2022

- February 2022

- January 2022

- December 2021

- November 2021

- October 2021

- September 2021

- August 2021

- July 2021

- June 2021

- May 2021

- April 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- October 2020

- September 2020

- August 2020

- July 2020

- June 2020

- May 2020

- April 2020

- March 2020

- February 2020

- January 2020

- December 2019

- November 2019

- October 2019

- September 2019

- August 2019

- July 2019

- June 2019

- May 2019

- April 2019

- March 2019

- February 2019

- January 2019

- December 2018

- November 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- March 2018

- February 2018

- January 2018

- December 2017

- November 2017

- October 2017

- September 2017

- August 2017

- July 2017

- June 2017

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017

- December 2016

- November 2016

- October 2016

- September 2016

- August 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- November 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- May 2015

- April 2015

- March 2015

- February 2015

- January 2015

- December 2014

- November 2014

- October 2014

- September 2014

- August 2014

- July 2014

- June 2014

- May 2014

- April 2014

- March 2014

- February 2014

- January 2014

- December 2013

- November 2013

- October 2013

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- February 2012

- January 2012

- December 2011

- November 2011

- October 2011

- September 2011

- August 2011

- July 2011

- June 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- September 2009

- August 2009

- July 2009

- June 2009

- May 2009

- April 2009

- March 2009

- February 2009

- January 2009

- December 2008

- November 2008

- October 2008

- September 2008

- August 2008

- July 2008

- June 2008

- May 2008

- April 2008

- March 2008

- February 2008

- January 2008

- December 2007

- November 2007

- October 2007

- September 2007

- August 2007

- June 2007

- February 2007

- January 2007

- October 2006

- April 2006

- January 2006

- April 2005

- December 2004

- November 2004

- December 1987

CATEGORIES

- About Us

- Advanced Biofuels Call to Action

- Aviation Fuel/Sustainable Aviation Fuel (SAF)

- BioChemicals/Renewable Chemicals

- BioRefineries/Renewable Fuel Production

- Business News/Analysis

- Cooking Fuel

- Education

- 30/30 Online Presentations

- Competitions, Contests

- Earth Day 2021

- Earth Day 2022

- Earth Day 2023

- Earth Day 2024

- Earth Day 2025

- Executive Training

- Featured Study Programs

- Instagram TikTok Short Videos

- Internships

- Just a Minute

- K-12 Activities

- Mechanics training

- Online Courses

- Podcasts

- Scholarships/Fellowships

- Teacher Resources

- Technical Training

- Technician Training

- University/College Programs

- Events

- Coming Events

- Completed Events

- More Coming Events

- Requests for Speakers, Presentations, Posters

- Requests for Speakers, Presentations, Posters Completed

- Webinars/Online

- Webinars/Online Completed; often available on-demand

- Federal Agency/Executive Branch

- Agency for International Development (USAID)

- Agriculture (USDA)

- Commerce Department

- Commodity Futures Trading Commission

- Congressional Budget Office

- Defense (DOD)

- Air Force

- Army

- DARPA (Defense Advance Research Projects Agency)

- Defense Logistics Agency

- Marines

- Navy

- Education Department

- Energy (DOE)

- Environmental Protection Agency

- Federal Energy Regulatory Commission (FERC)

- Federal Reserve System

- Federal Trade Commission

- Food and Drug Administration

- General Services Administration

- Government Accountability Office (GAO)

- Health and Human Services (HHS)

- Homeland Security

- Housing and Urban Development (HUD)

- Interior Department

- International Trade Commission

- Joint Office of Energy and Transportation

- Justice (DOJ)

- Labor Department

- National Academies of Sciences Engineering Medicine

- National Aeronautics and Space Administration

- National Oceanic and Atmospheric Administration

- National Research Council

- National Science Foundation

- National Transportation Safety Board (NTSB)

- Occupational Safety and Health Administration

- Overseas Private Investment Corporation

- Patent and Trademark Office

- Securities and Exchange Commission

- State Department

- Surface Transportation Board

- Transportation (DOT)

- Federal Aviation Administration

- National Highway Traffic Safety Administration (NHTSA)

- Pipeline and Hazardous Materials Safety Admin (PHMSA)

- Treasury Department

- U.S. Trade Representative (USTR)

- White House

- Federal Legislation

- Federal Litigation

- Federal Regulation

- Feedstocks

- Agriculture/Food Processing Residues nonfield crop

- Alcohol/Ethanol/Isobutanol

- Algae/Other Aquatic Organisms/Seaweed

- Atmosphere

- Carbon Dioxide (CO2)

- Field/Orchard/Plantation Crops/Residues

- Forestry/Wood/Residues/Waste

- hydrogen

- Manure

- Methane/Biogas

- methanol/bio-/renewable methanol

- Not Agriculture

- RFNBO (Renewable Fuels of Non-Biological Origin)

- Seawater

- Sugars

- water

- Funding/Financing/Investing

- grants

- Green Jobs

- Green Racing

- Health Concerns/Benefits

- Heating Oil/Fuel

- History of Advanced Biofuels

- Infrastructure

- Aggregation

- Biofuels Engine Design

- Biorefinery/Fuel Production Infrastructure

- Carbon Capture/Storage/Use

- certification

- Deliver Dispense

- Farming/Growing

- Precursors/Biointermediates

- Preprocessing

- Pretreatment

- Terminals Transport Pipelines

- International

- Abu Dhabi

- Afghanistan

- Africa

- Albania

- Algeria

- Angola

- Antarctica

- Arctic

- Argentina

- Armenia

- Aruba

- Asia

- Asia Pacific

- Australia

- Austria

- Azerbaijan

- Bahamas

- Bahrain

- Bangladesh

- Barbados

- Belarus

- Belgium

- Belize

- Benin

- Bermuda

- Bhutan

- Bolivia

- Bosnia and Herzegovina

- Botswana

- Brazil

- Brunei

- Bulgaria

- Burkina Faso

- Burundi

- Cambodia

- Cameroon

- Canada

- Caribbean

- Central African Republic

- Central America

- Chad

- Chile

- China

- Colombia

- Congo

- Congo, Democratic Republic of

- Costa Rica

- Croatia

- Cuba

- Cyprus

- Czech Republic

- Denmark

- Dominican Republic

- Dubai

- Ecuador

- El Salvador

- Equatorial Guinea

- Eqypt

- Estonia

- Eswatini/Swaziland

- Ethiopia

- European Union (EU)

- Fiji

- Finland

- France

- French Guiana

- Gabon

- Georgia

- Germany

- Ghana

- Global South

- Greece

- Greenland

- Grenada

- Guatemala

- Guinea

- Guyana

- Haiti

- Honduras

- Hong Kong

- Hungary

- Iceland

- India

- Indonesia

- Iran

- Iraq

- Ireland

- Israel

- Italy

- Ivory Coast

- Jamaica

- Japan

- Jersey

- Jordan

- Kazakhstan

- Kenya

- Korea

- Kosovo

- Kuwait

- Laos

- Latin America

- Latvia

- Lebanon

- Liberia

- Lithuania

- Luxembourg

- Macedonia

- Madagascar

- Malawi

- Malaysia

- Maldives

- Mali

- Malta

- Marshall Islands

- Mauritania

- Mauritius

- Mexico

- Middle East

- Moldova

- Monaco

- Mongolia

- Morocco

- Mozambique

- Myanmar/Burma

- Namibia

- Nepal

- Netherlands

- New Guinea

- New Zealand

- Nicaragua

- Niger

- Nigeria

- North Africa

- North America

- North Korea

- Northern Ireland

- Norway

- Oman

- Pakistan

- Panama

- Papua New Guinea

- Paraguay

- Peru

- Philippines

- Poland

- Portugal

- Qatar

- Republic of

- Romania

- Russia

- Rwanda

- Saudi Arabia

- Scotland

- Senegal

- Serbia

- Sierra Leone

- Singapore

- Slovakia

- Slovenia

- Solomon Islands

- South Africa

- South America

- South Korea

- South Sudan

- Southeast Asia

- Spain

- Sri Lanka

- Sudan

- Suriname

- Sweden

- Switzerland

- Taiwan

- Tanzania

- Thailand

- Timor-Leste

- Togo

- Trinidad and Tobago

- Tunisia

- Turkey

- Uganda

- UK (United Kingdom)

- Ukraine

- United Arab Emirates UAE

- Uruguay

- Uzbekistan

- Vatican

- Venezuela

- Vietnam

- Wales

- Zambia

- Zanzibar

- Zimbabwe

- Marine/Boat Bio and Renewable Fuel/MGO/MDO/SMF

- Marketing/Market Forces and Sales

- Opinions

- Organizations

- Original Writing, Opinions Advanced Biofuels USA

- Policy

- Presentations

- Biofuels Digest Conferences

- DOE Conferences

- Bioeconomy 2017

- Bioenergy2015

- Biomass2008

- Biomass2009

- Biomass2010

- Biomass2011

- Biomass2012

- Biomass2013

- Biomass2014

- DOE Project Peer Review

- Other Conferences/Events

- R & D Focus

- Carbon Capture/Storage/Use

- Co-Products

- Feedstock

- Logistics

- Performance

- Process

- Vehicle/Engine/Motor/Aircraft/Boiler

- Yeast

- Railroad/Train/Locomotive Fuel

- Resources

- Books Web Sites etc

- Business

- Definition of Advanced Biofuels

- Find Stuff

- Government Resources

- Scientific Resources

- Technical Resources

- Tools/Decision-Making

- Rocket/Missile Fuel

- Sponsors

- States

- Alabama

- Alaska

- Arizona

- Arkansas

- California

- Colorado

- Connecticut

- Delaware

- Florida

- Georgia

- Hawai'i

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Kentucky

- Louisiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Midwest

- Minnesota

- Mississippi

- Missouri

- Montana

- Native American tribal nation lands

- Nebraska

- Nevada

- New Hampshire

- New Jersey

- New Mexico

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Puerto Rico

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- Washington DC

- West Coast

- West Virginia

- Wisconsin

- Wyoming

- Sustainability

- Uncategorized

- What You Can Do

tags

© 2008-2023 Copyright Advanced BioFuels USA. All Rights reserved.

.jpg)

0 COMMENTS

Leave A Comment

Your Email Address wiil not be Published. Required Field Are marked*